Peripheral Equipments

Peripheral equipment's include Conveyor belts, pneumatic conveyors, electromechanical transporters, Ball bearing inserts, ball bearing rails, roller inserts, roller rails, spring mounted rollers, counter view.

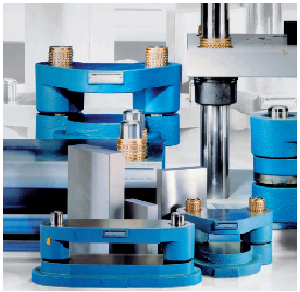

Ball bearing inserts and rails

The ball bearing inserts and rails helps to move or change tools fast, and above all accurately - even if they weigh several tons. Equipping and retrofitting press tables with ball bearing rails is extremely straightforward as virtually every press table has fixing slots. The ball bearing rails are simply inserted and fixed in these slots. Ball bearing inserts can be used for press tables which do not have fixing slots. These are fitted in the locating sockets. The ball bearings of the inserts and rails will move in any direction and project only slightly above the surface of the press table. The result is that only slight force is required for movement on the table. When the tool is clamped in place it sits on the table and the clamping pressure causes the ball bearings to retract into their sockets.

Available products:

- Ball bearing insert with/without collar

- Ball bearing rail

Roller inserts and roller rails

Roller inserts and rails will carry twice the load of ball bearing inserts and rails and ensure precise linear movement of the tool. This linear technology requires precise positioning of the tool when it is transferred to the tool bench. Roller rails are used especially on presses with stationary mounting devices. The special roller bearing technology operates reliably at high temperatures 200° C ). Unlike ball bearing rails, roller rails can be used in tool base plates i.e. installed upside down.

Available products:

- Roller insert with/without collar

- Roller Rail Spring mounted roller to VW Standard

- Roller Rail

- Spring mounted roller to VW Standard

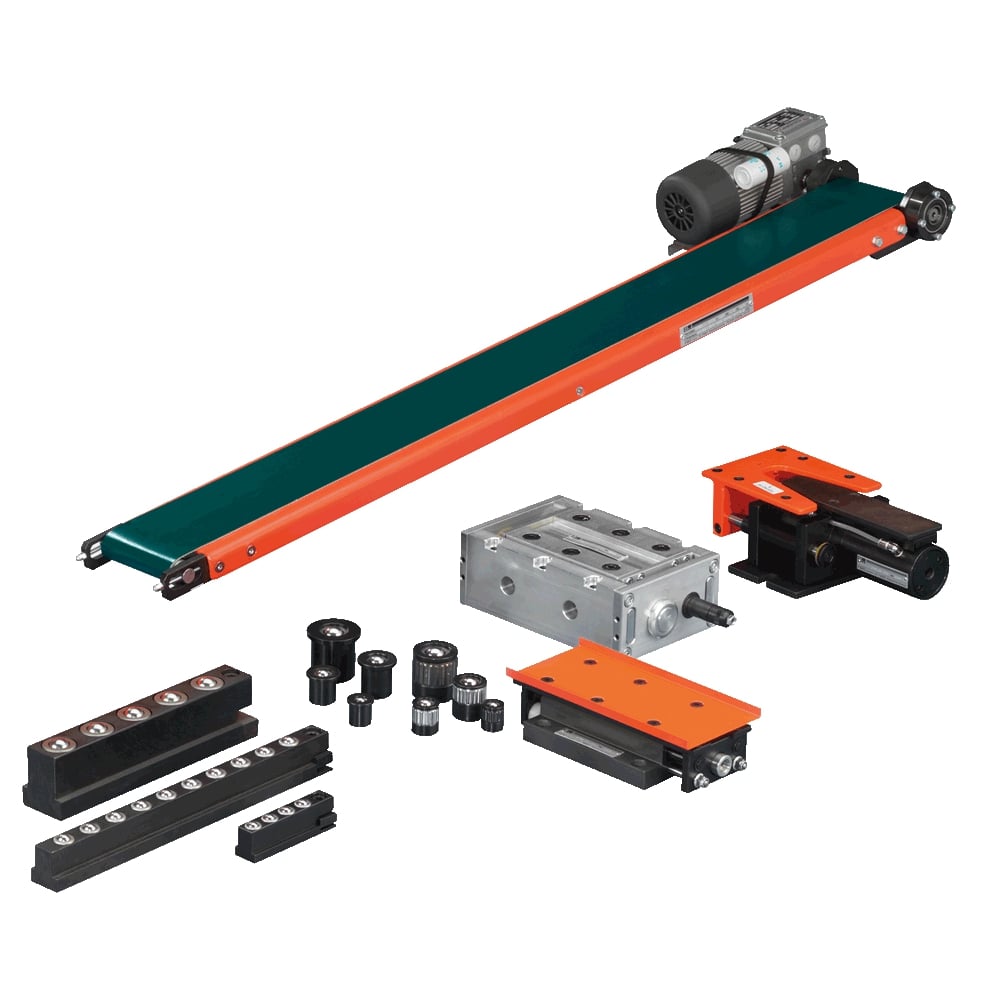

Conveyor Belts

Conveyor belts are designed for use in a wide variety of production applications. There is a belt width and length to suit almost every application.

The conveyor belts are powered by an electric motor, which is electronically regulated to provide belt speeds from 0.02 to 30 meters per minute.

The motor can be mounted horizontally or vertically, on either side of the belt for either direction of movement. Conveyor belts are available with or without profiles across the belt. Conveyor edge rails are also available in a range of designs.

Available products:

- Electrically controlled conveyor belt

- Delimiting guide for conveyor belt

- Delimiting guide with loss prevention for conveyor belt

- Stand for conveyor belt

Pneumatic Conveyors

Pneumatic conveyor is unique and is patented. It was designed to provide an effective and affordable solution to the problems of conveying parts and disposing of waste. This beltless system conveys stampings and waste from the tool area by vibration alone.

Available products:

- Pneumatic Conveyors

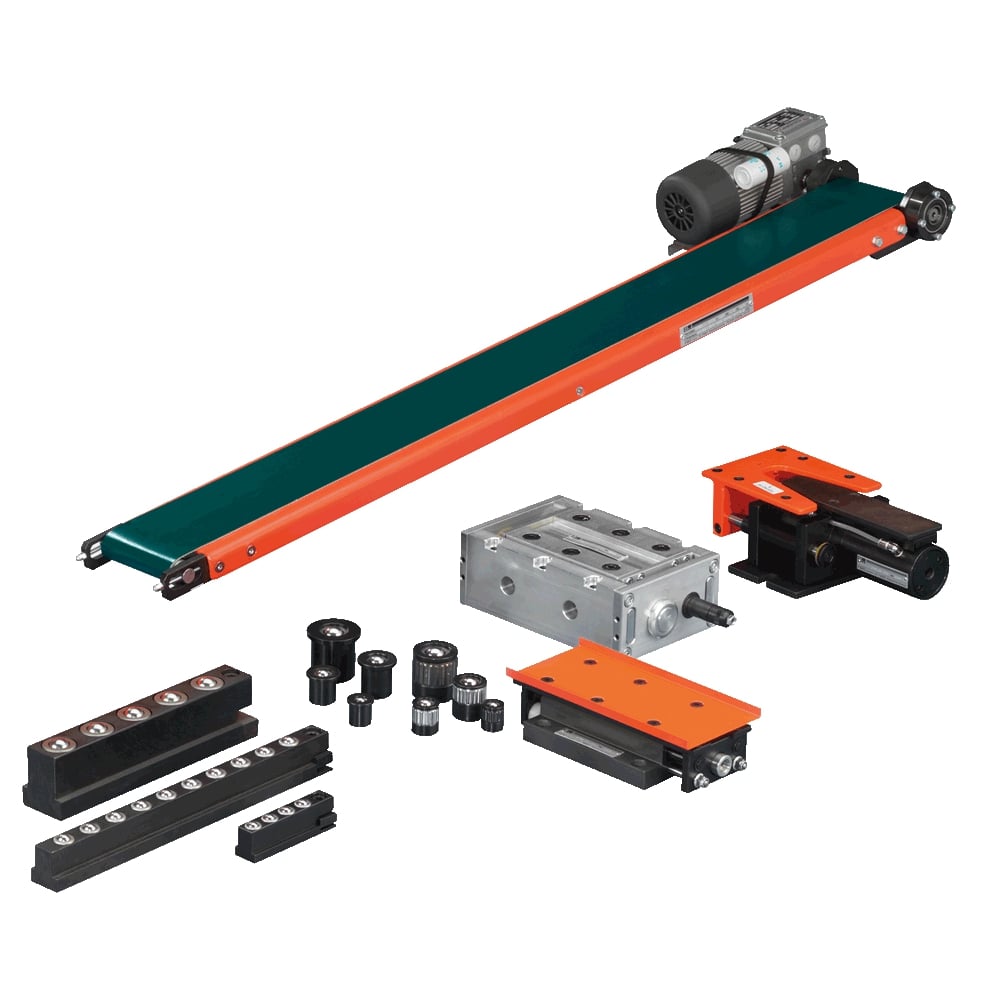

Electro-mechanical Transporters

Electro-mechanical transporters have been developed to effectively and inexpensively solve the problems of transporting parts and the removal of stamping and cutting residues from presses. The principle behind the electro-mechanical transporter is the so-called "table cloth effect“. The slow acceleration during the forward stroke pushes the parts or offcuts forwards. The fast return stroke of the guiding system results in a transport movement in only one direction.

Available products:

- Electro-mechanical transporter-vertical gear position

- Electro-mechanical transporter-horizontal gear position

- Electro-mechanical transporter-vertical gear position, with profile and support

- Electro-mechanical transporter-horizontal gear position, with profile and support

- Electro-mechanical transporter-vertical gear position, two slides, with profile and support

- Electro-mechanical transporter-horizontal gear position, two slides, with profile and support

- Electro-mechanical transporter-vertical center gear position, two slides, with profile and support

- Electro-mechanical transporter-horizontal center gear position, two slides, with profile and support

- Electro-mechanical transporter-Fastening element with/without height adjustment system

- Electro-mechanical transporter-Quick clamp for guiding system

- Electro-mechanical transporter-Angled mounting with adapter plate

- Sensors for stamping and forming technology.

Enquire Form

Need Help?

+971 4 289 6166

Peripheral Equipments

Peripheral equipment's include Conveyor belts, pneumatic conveyors, electromechanical transporters, Ball bearing inserts, ball bearing rails, roller inserts, roller rails, spring mounted rollers, counter view.

Ball bearing inserts and rails

The ball bearing inserts and rails helps to move or change tools fast, and above all accurately - even if they weigh several tons. Equipping and retrofitting press tables with ball bearing rails is extremely straightforward as virtually every press table has fixing slots. The ball bearing rails are simply inserted and fixed in these slots. Ball bearing inserts can be used for press tables which do not have fixing slots. These are fitted in the locating sockets. The ball bearings of the inserts and rails will move in any direction and project only slightly above the surface of the press table. The result is that only slight force is required for movement on the table. When the tool is clamped in place it sits on the table and the clamping pressure causes the ball bearings to retract into their sockets.

Available products:

- Ball bearing insert with/without collar

- Ball bearing rail

Roller inserts and roller rails

Roller inserts and rails will carry twice the load of ball bearing inserts and rails and ensure precise linear movement of the tool. This linear technology requires precise positioning of the tool when it is transferred to the tool bench. Roller rails are used especially on presses with stationary mounting devices. The special roller bearing technology operates reliably at high temperatures 200° C ). Unlike ball bearing rails, roller rails can be used in tool base plates i.e. installed upside down.

Available products:

- Roller insert with/without collar

- Roller Rail Spring mounted roller to VW Standard

- Roller Rail

- Spring mounted roller to VW Standard

Conveyor Belts

Conveyor belts are designed for use in a wide variety of production applications. There is a belt width and length to suit almost every application.

The conveyor belts are powered by an electric motor, which is electronically regulated to provide belt speeds from 0.02 to 30 meters per minute.

The motor can be mounted horizontally or vertically, on either side of the belt for either direction of movement. Conveyor belts are available with or without profiles across the belt. Conveyor edge rails are also available in a range of designs.

Available products:

- Electrically controlled conveyor belt

- Delimiting guide for conveyor belt

- Delimiting guide with loss prevention for conveyor belt

- Stand for conveyor belt

Pneumatic Conveyors

Pneumatic conveyor is unique and is patented. It was designed to provide an effective and affordable solution to the problems of conveying parts and disposing of waste. This beltless system conveys stampings and waste from the tool area by vibration alone.

Available products:

- Pneumatic Conveyors

Electro-mechanical Transporters

Electro-mechanical transporters have been developed to effectively and inexpensively solve the problems of transporting parts and the removal of stamping and cutting residues from presses. The principle behind the electro-mechanical transporter is the so-called "table cloth effect“. The slow acceleration during the forward stroke pushes the parts or offcuts forwards. The fast return stroke of the guiding system results in a transport movement in only one direction.

Available products:

- Electro-mechanical transporter-vertical gear position

- Electro-mechanical transporter-horizontal gear position

- Electro-mechanical transporter-vertical gear position, with profile and support

- Electro-mechanical transporter-horizontal gear position, with profile and support

- Electro-mechanical transporter-vertical gear position, two slides, with profile and support

- Electro-mechanical transporter-horizontal gear position, two slides, with profile and support

- Electro-mechanical transporter-vertical center gear position, two slides, with profile and support

- Electro-mechanical transporter-horizontal center gear position, two slides, with profile and support

- Electro-mechanical transporter-Fastening element with/without height adjustment system

- Electro-mechanical transporter-Quick clamp for guiding system

- Electro-mechanical transporter-Angled mounting with adapter plate

- Sensors for stamping and forming technology.

Enquire Form