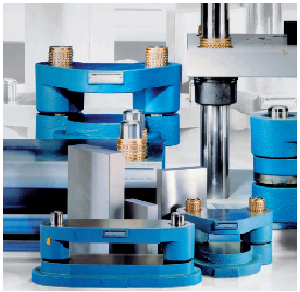

Precision Components

Precision components offer exceptional versatility and durability for various industrial applications. Designed from high-quality materials like Alloy Tool Steel, High-Speed Steel, and Tungsten Carbide, these components include punches, matrices, pins, and gauge pins.

Product Features:

Precision components come in various materials, shapes, and sizes, allowing for a high degree of customization to meet specific and complex requirements.

These components are designed for long-lasting performance, significantly reducing the frequency of tool changes and cutting operational costs.

Continuous quality monitoring throughout the production ensures that every component meets stringent standards, contributing to an exceptionally long die life.

Applications:

Precision components are designed to meet the highest standards of performance and durability, ensuring efficient and cost-effective solutions for a range of industrial applications.

Ideal for punching, embossing, and forming operations within metalworking industries.

Utilized in the production of dies and molds, particularly where high wear resistance and precision are critical.

Used in manufacturing components for automotive and aerospace applications, where precision and durability are paramount.

Industries:

Automotive

Aerospace

Tooling and Machinery

Specifications:

Materials:

WS: Alloy Tool Steel

HWS: High Carbon - High Chrome Tool Steel

HSS: High-Speed Steel

ASP 23/2023: High-Speed Steel on Powder-Metallurgic Basis

HST: High-Speed Steel, Nitride

FT: Ferro-Tic (Ferro Titanite)

HZ: Hard-coated Tooling Components

HM: Tungsten Carbide

NWA: Hot-work Tool Steel, Suitable for Nitriding

Product Types:

Punches and Matrices: Various shapes including DIN 9861, DIN 9844, ISO 8020, and custom designs.

Pins and Gauge Pins: Including ball lock pins, pilot pins, and gauge pin sets.

Guide Bushes: For different standard punches and matrices.

Dynamic Stripping Elements (DAE): For enhanced functionality in stripping operations.

Stripping Units: Pressure and mounting plates for efficient material handling.

Special Components: Including elastomer strippers, dowel pins, drill bushes, and more.

Customization:

Available in multiple shapes and configurations, including tapered heads, stepped designs, and custom profiles to suit specific operational needs.

Enquire Form

Need Help?

+971 4 289 6166

Precision Components

Precision components offer exceptional versatility and durability for various industrial applications. Designed from high-quality materials like Alloy Tool Steel, High-Speed Steel, and Tungsten Carbide, these components include punches, matrices, pins, and gauge pins.

Product Features:

Precision components come in various materials, shapes, and sizes, allowing for a high degree of customization to meet specific and complex requirements.

These components are designed for long-lasting performance, significantly reducing the frequency of tool changes and cutting operational costs.

Continuous quality monitoring throughout the production ensures that every component meets stringent standards, contributing to an exceptionally long die life.

Applications:

Precision components are designed to meet the highest standards of performance and durability, ensuring efficient and cost-effective solutions for a range of industrial applications.

Ideal for punching, embossing, and forming operations within metalworking industries.

Utilized in the production of dies and molds, particularly where high wear resistance and precision are critical.

Used in manufacturing components for automotive and aerospace applications, where precision and durability are paramount.

Industries:

Automotive

Aerospace

Tooling and Machinery

Specifications:

Materials:

WS: Alloy Tool Steel

HWS: High Carbon - High Chrome Tool Steel

HSS: High-Speed Steel

ASP 23/2023: High-Speed Steel on Powder-Metallurgic Basis

HST: High-Speed Steel, Nitride

FT: Ferro-Tic (Ferro Titanite)

HZ: Hard-coated Tooling Components

HM: Tungsten Carbide

NWA: Hot-work Tool Steel, Suitable for Nitriding

Product Types:

Punches and Matrices: Various shapes including DIN 9861, DIN 9844, ISO 8020, and custom designs.

Pins and Gauge Pins: Including ball lock pins, pilot pins, and gauge pin sets.

Guide Bushes: For different standard punches and matrices.

Dynamic Stripping Elements (DAE): For enhanced functionality in stripping operations.

Stripping Units: Pressure and mounting plates for efficient material handling.

Special Components: Including elastomer strippers, dowel pins, drill bushes, and more.

Customization:

Available in multiple shapes and configurations, including tapered heads, stepped designs, and custom profiles to suit specific operational needs.

Enquire Form