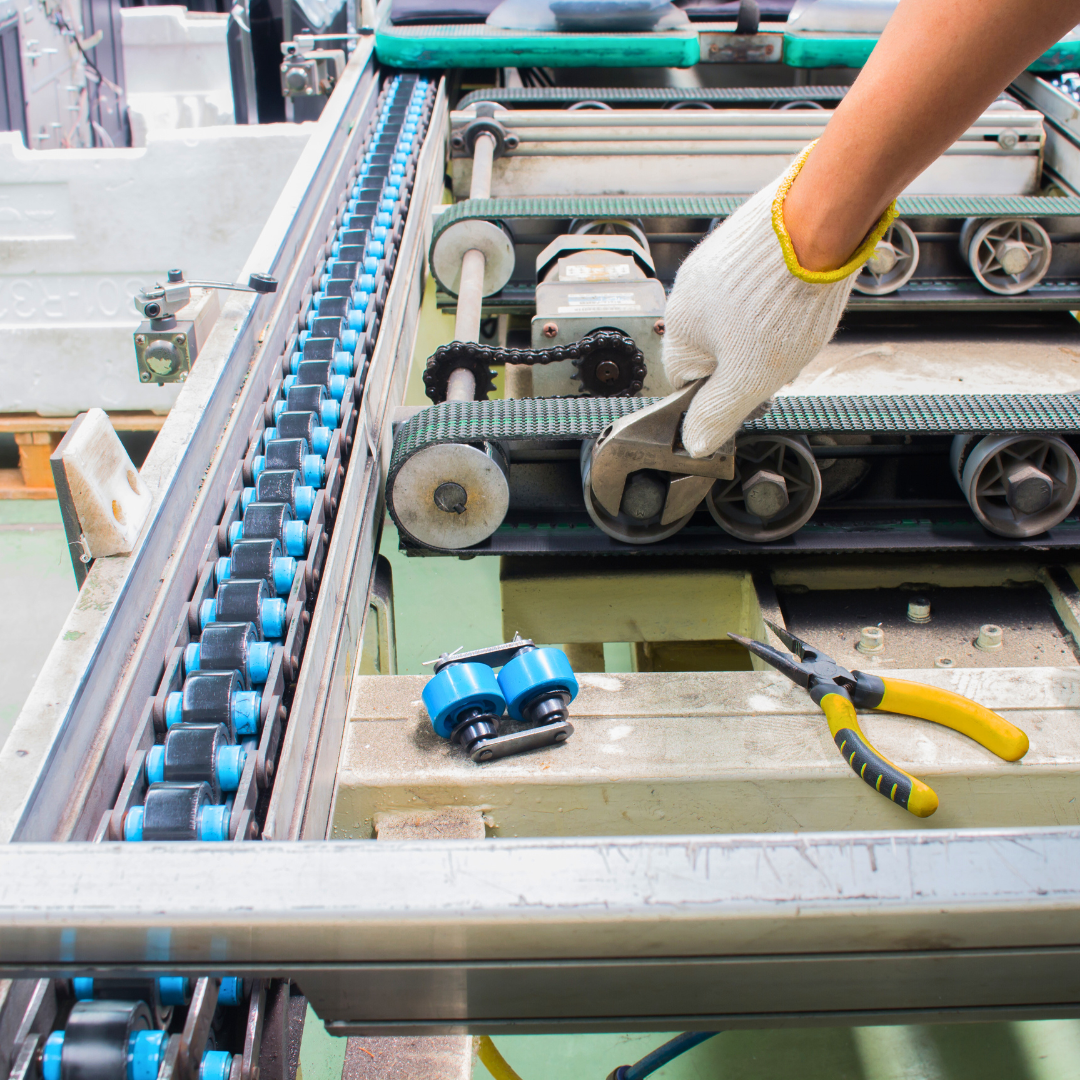

Sterilizer Chains

Sterilizer chains are robust, high-quality chains designed specifically for use in sterilization processes. These chains are built to withstand the rigorous conditions of high temperatures, moisture, and exposure to various sterilizing agents, ensuring longevity and reliability.

Product Features:

Constructed from heat-resistant materials to ensure durability.

Made from stainless steel or specially coated to resist corrosion from chemicals and sterilizing agents and prolong the life of the chain, reducing maintenance costs.

Enhanced strength to endure continuous and rigorous sterilization cycles.

Minimal wear and tear under high-stress conditions.

Designed for smooth operation in various sterilization equipment.

Adaptable to different sizes and configurations.

Smooth surfaces to prevent bacteria build-up.

Easy to clean and maintain.

Applications:

Sterilizer chains are essential in maintaining the highest standards of hygiene and safety across various industries, ensuring that equipment and environments remain sterile and free from contaminants.

Sterilization of surgical instruments and medical devices.

Autoclaves and sterilization tunnels.

Ensuring cleanliness in food processing equipment.

Helps in contamination-free environments in research facilities.

Industries:

Healthcare and Medical Devices

Food and Beverage Processing

Pharmaceutical Manufacturing

Biotechnology and Laboratories

Cosmetics and Personal Care Products

Specifications

Material: Stainless Steel (Grade 304, 316, or custom) Coated Carbon Steel (Nickel, Chrome, etc.)

Temperature Range: Operating temperature: -20°C to 300°C (-4°F to 572°F)

Chain Size: Pitch: 0.5 to 2 inches (custom sizes available)

Length: Custom lengths as per application requirements

Enquire Form

Need Help?

+971 4 289 6166

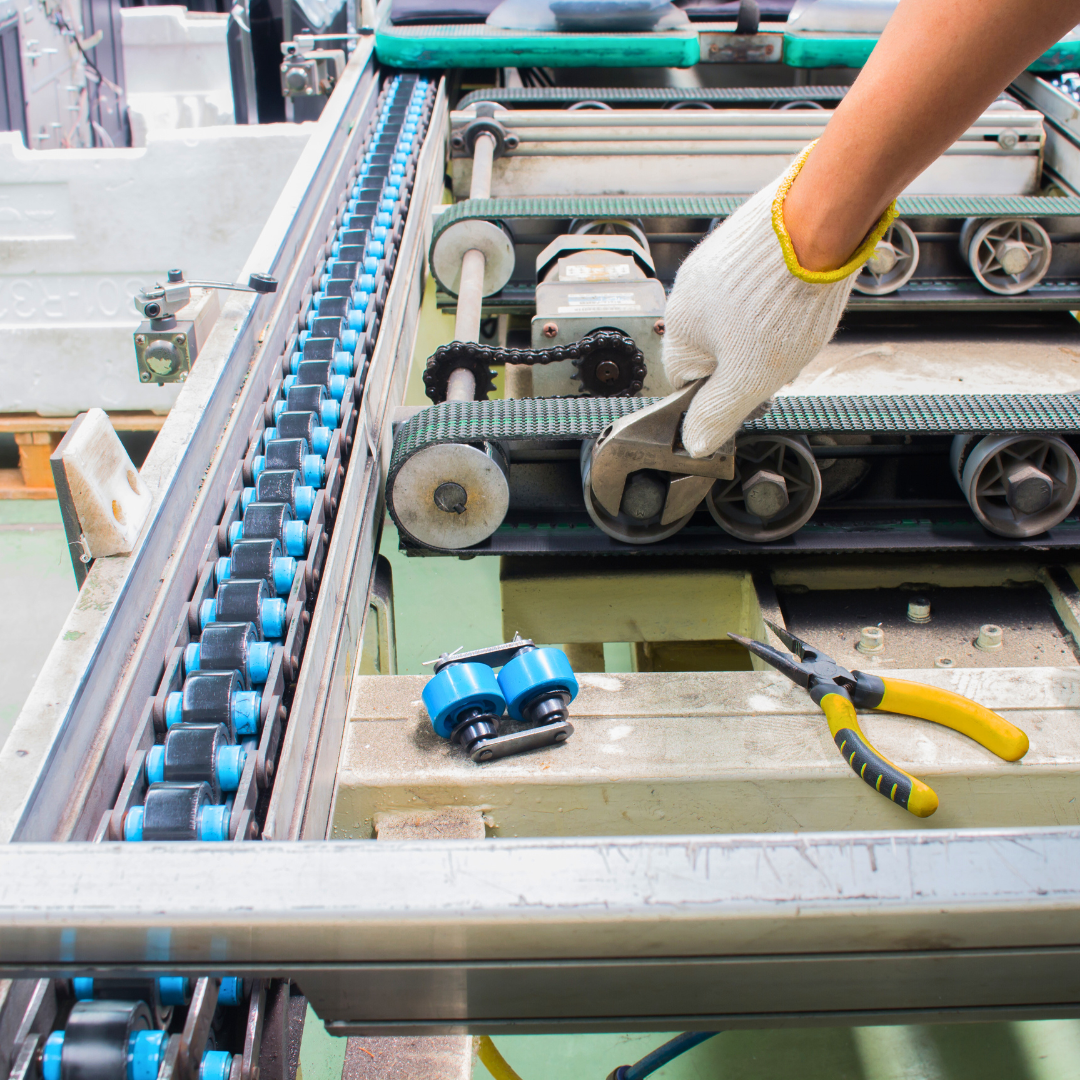

Sterilizer Chains

Sterilizer chains are robust, high-quality chains designed specifically for use in sterilization processes. These chains are built to withstand the rigorous conditions of high temperatures, moisture, and exposure to various sterilizing agents, ensuring longevity and reliability.

Product Features:

Constructed from heat-resistant materials to ensure durability.

Made from stainless steel or specially coated to resist corrosion from chemicals and sterilizing agents and prolong the life of the chain, reducing maintenance costs.

Enhanced strength to endure continuous and rigorous sterilization cycles.

Minimal wear and tear under high-stress conditions.

Designed for smooth operation in various sterilization equipment.

Adaptable to different sizes and configurations.

Smooth surfaces to prevent bacteria build-up.

Easy to clean and maintain.

Applications:

Sterilizer chains are essential in maintaining the highest standards of hygiene and safety across various industries, ensuring that equipment and environments remain sterile and free from contaminants.

Sterilization of surgical instruments and medical devices.

Autoclaves and sterilization tunnels.

Ensuring cleanliness in food processing equipment.

Helps in contamination-free environments in research facilities.

Industries:

Healthcare and Medical Devices

Food and Beverage Processing

Pharmaceutical Manufacturing

Biotechnology and Laboratories

Cosmetics and Personal Care Products

Specifications

Material: Stainless Steel (Grade 304, 316, or custom) Coated Carbon Steel (Nickel, Chrome, etc.)

Temperature Range: Operating temperature: -20°C to 300°C (-4°F to 572°F)

Chain Size: Pitch: 0.5 to 2 inches (custom sizes available)

Length: Custom lengths as per application requirements

Enquire Form