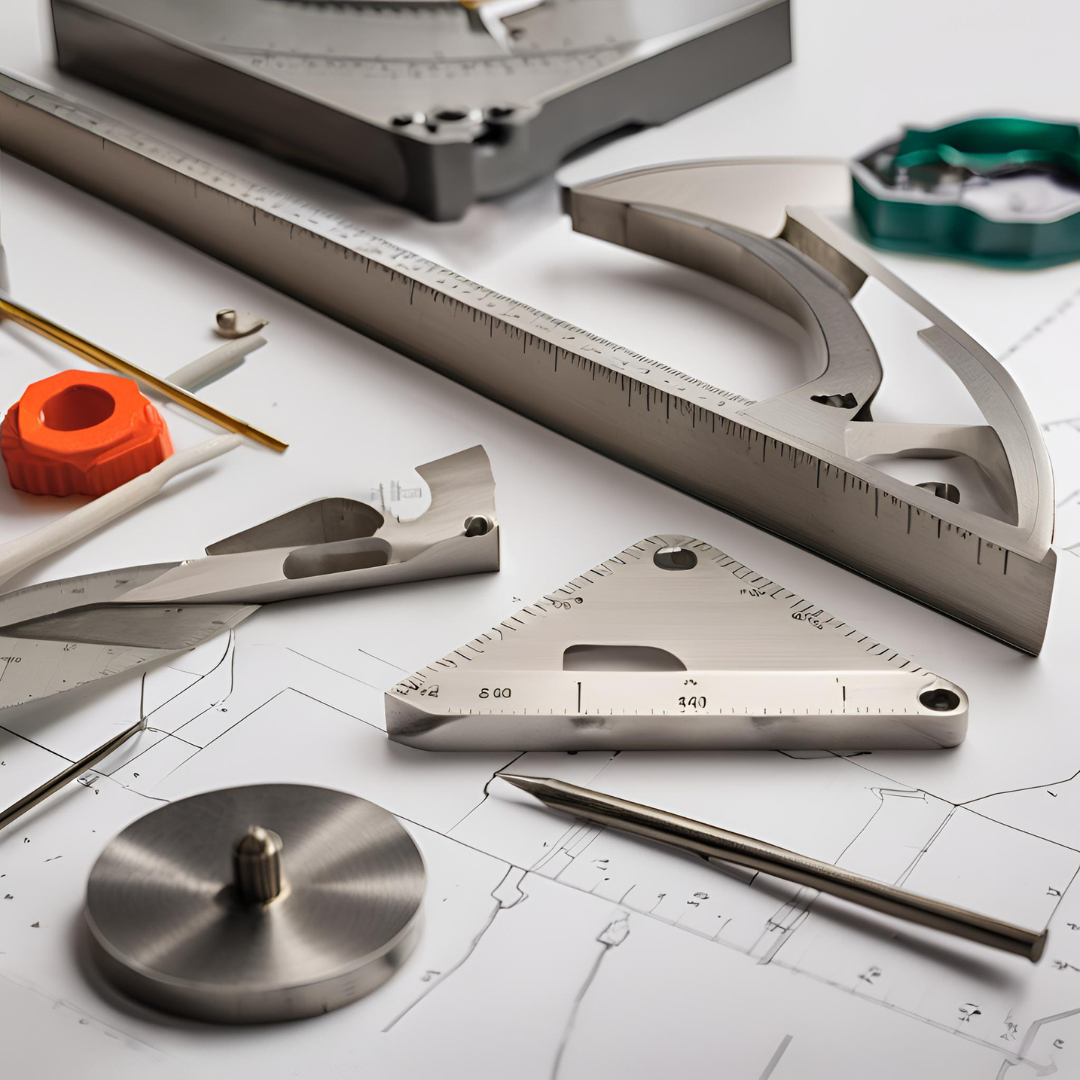

Precision Tools

Engineering precision tools are specialized instruments designed to measure, inspect, and fabricate components with exceptional accuracy. These tools include micrometers, calipers, dial indicators, height gauges, and more, essential for applications in quality control, machining, and research and development.

Product Features:

Tools designed with cutting-edge technology to ensure precise measurements and machining.

Made from high-quality materials like hardened steel and carbide for longevity and resistance to wear.

User-friendly features for comfortable handling and reduced operator fatigue.

Includes micrometers, calipers, dial indicators, height gauges, and more, suitable for various measurement tasks.

Available in both digital for easy readouts and traditional analog for those who prefer classic tools.

Comes with certification for accuracy, ensuring tools meet industry standards.

Applications:

Engineering precision tools are indispensable in any setting where exact measurements are critical, ensuring the highest quality and performance in products and projects.

Ensure parts and components meet specified tolerances.

Used in the production of precision parts for industries such as aerospace, automotive, and electronics.

Critical in the development of new products and technologies, requiring precise measurements.

Vital in creating molds and dies with exact specifications.

Ensures parts fit together correctly, avoiding assembly errors and ensuring product functionality.

Industries:

Architecture

Aerospace

Construction

Manufacturing

Automotive

Specifications:

Measurement Range: Varies per tool, e.g., micrometers from 0-25mm to 0-300mm, calipers up to 1500mm.

Resolution: As fine as 0.001mm for high-precision tasks.

Material: Hardened stainless steel, carbide tips, and other durable materials.

Accuracy: Within ±0.002mm, depending on the tool type.

Display: Digital models feature LCD screens; analog models have clear, easy-to-read scales.

Power Source: Digital tools typically powered by batteries, with some models offering rechargeable options.

Enquire Form

Need Help?

+971 4 289 6166

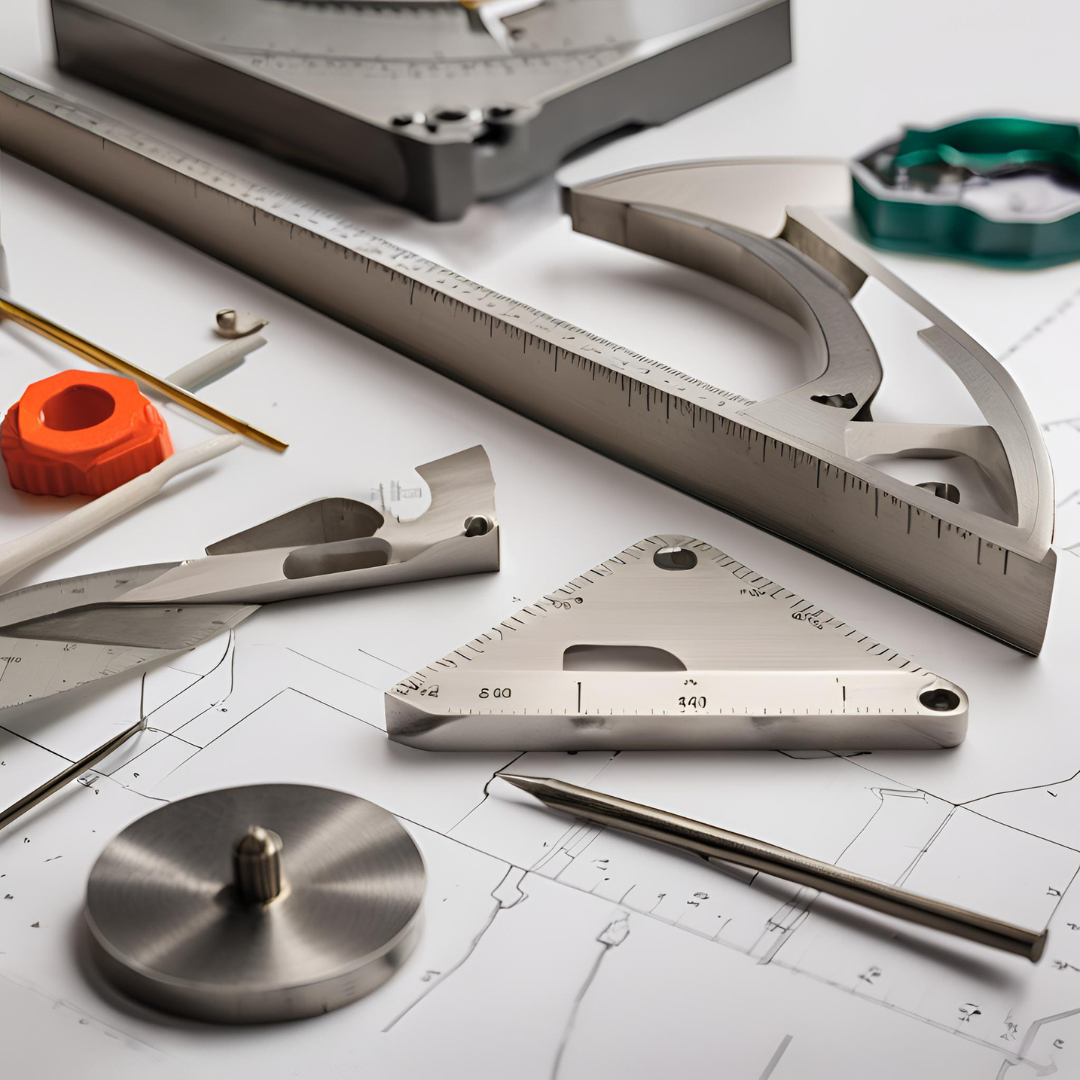

Precision Tools

Engineering precision tools are specialized instruments designed to measure, inspect, and fabricate components with exceptional accuracy. These tools include micrometers, calipers, dial indicators, height gauges, and more, essential for applications in quality control, machining, and research and development.

Product Features:

Tools designed with cutting-edge technology to ensure precise measurements and machining.

Made from high-quality materials like hardened steel and carbide for longevity and resistance to wear.

User-friendly features for comfortable handling and reduced operator fatigue.

Includes micrometers, calipers, dial indicators, height gauges, and more, suitable for various measurement tasks.

Available in both digital for easy readouts and traditional analog for those who prefer classic tools.

Comes with certification for accuracy, ensuring tools meet industry standards.

Applications:

Engineering precision tools are indispensable in any setting where exact measurements are critical, ensuring the highest quality and performance in products and projects.

Ensure parts and components meet specified tolerances.

Used in the production of precision parts for industries such as aerospace, automotive, and electronics.

Critical in the development of new products and technologies, requiring precise measurements.

Vital in creating molds and dies with exact specifications.

Ensures parts fit together correctly, avoiding assembly errors and ensuring product functionality.

Industries:

Architecture

Aerospace

Construction

Manufacturing

Automotive

Specifications:

Measurement Range: Varies per tool, e.g., micrometers from 0-25mm to 0-300mm, calipers up to 1500mm.

Resolution: As fine as 0.001mm for high-precision tasks.

Material: Hardened stainless steel, carbide tips, and other durable materials.

Accuracy: Within ±0.002mm, depending on the tool type.

Display: Digital models feature LCD screens; analog models have clear, easy-to-read scales.

Power Source: Digital tools typically powered by batteries, with some models offering rechargeable options.

Enquire Form