Plain Brass

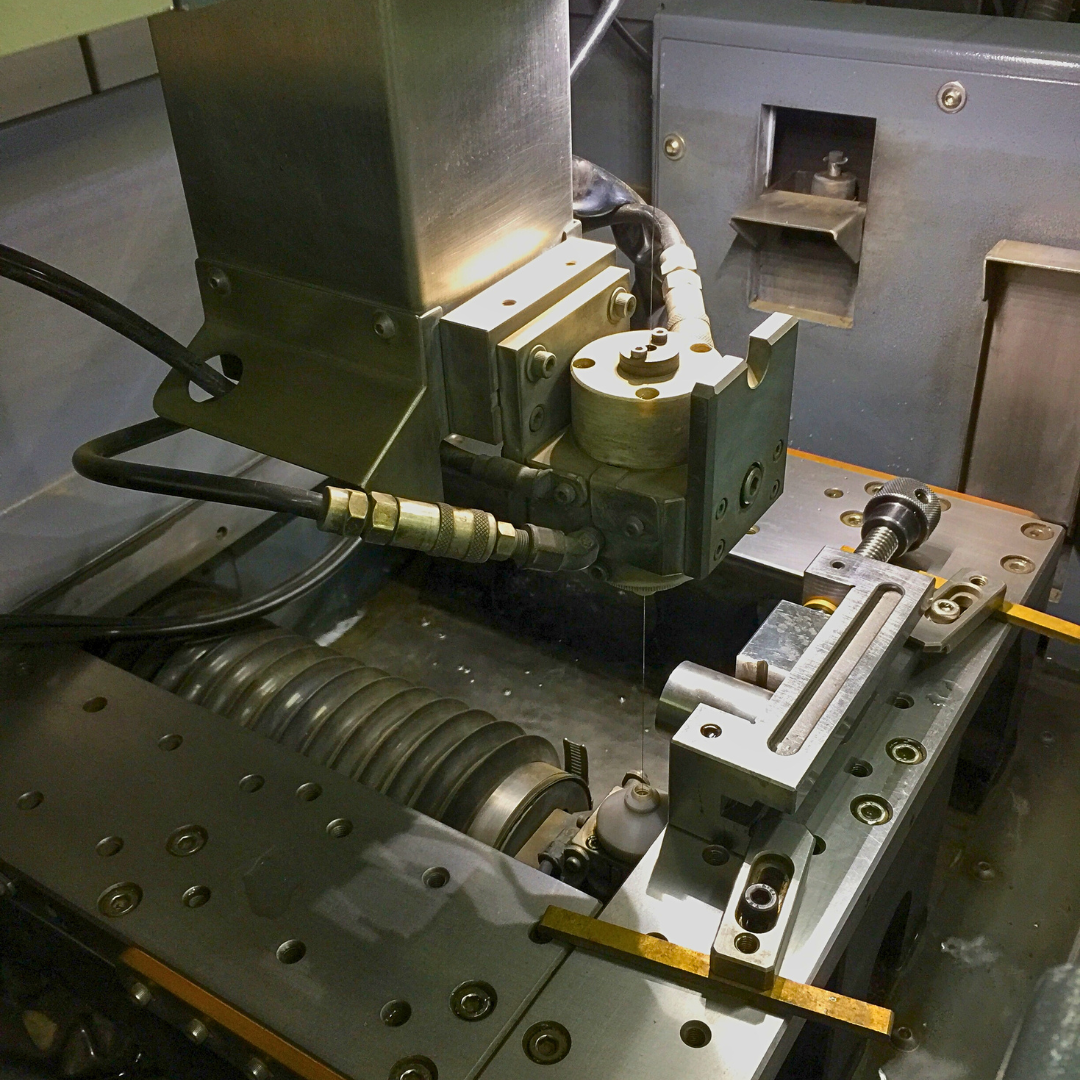

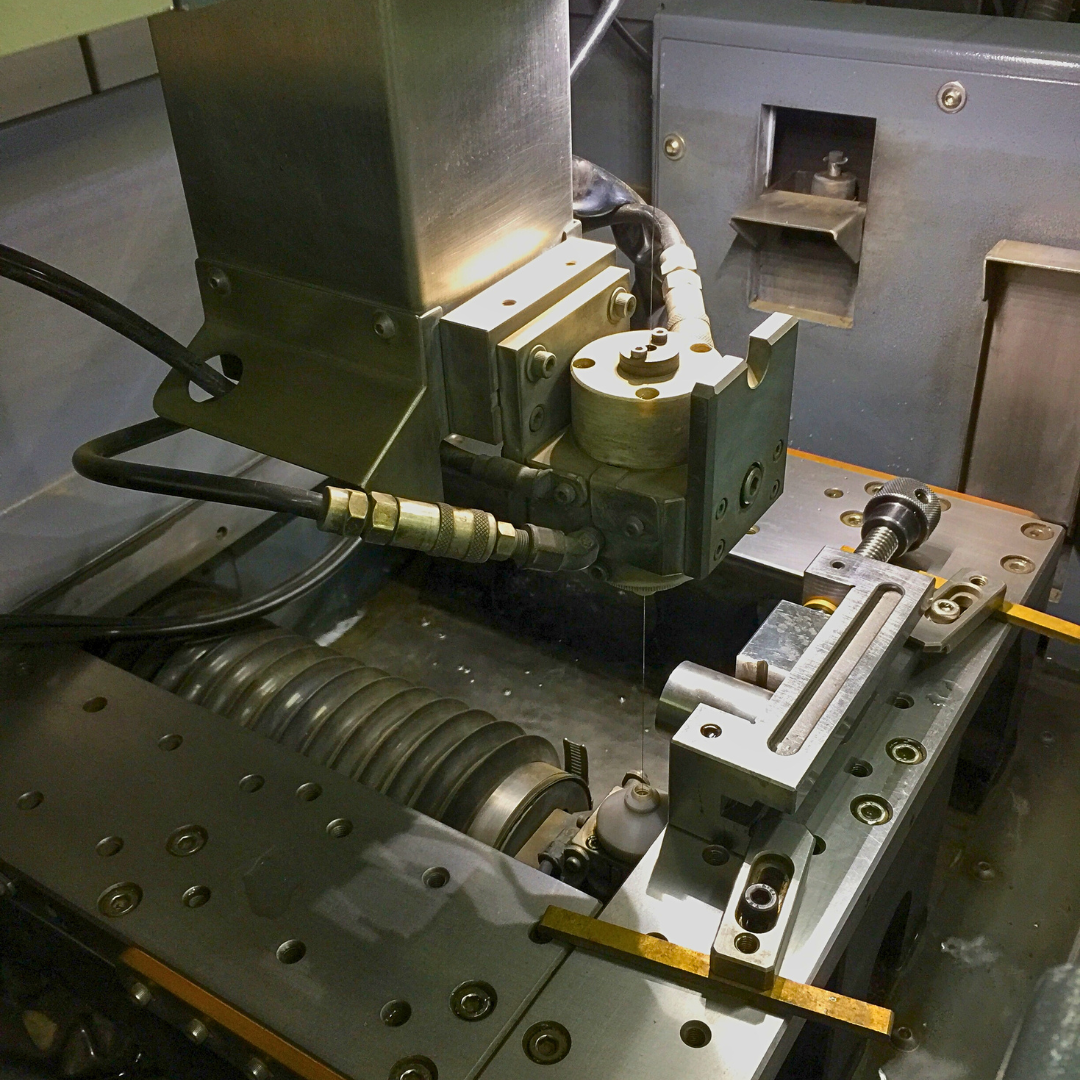

EDM wire is a critical component in the Electrical Discharge Machining (EDM) process, which is used for the precision cutting of complex shapes in conductive materials. This wire acts as the electrode through which electrical discharges or sparks are generated to erode material from the workpiece.

Product Features:

Available in various strengths to handle different stress levels during the EDM process. Higher tensile strength options are available for demanding applications.

Engineered for durability, ensuring the wire can withstand mechanical stresses without breaking.

High electrical conductivity, with brass wires being a popular choice for superior performance.

Made from materials with high vaporization temperatures to prevent premature breaking under extreme heat.

Hardness: Hard Brass Wires- For applications requiring high wear resistance, Semi-Hard Brass Wires- Balanced wear resistance and flexibility, Soft Brass Wires- Ideal where flexibility is more important than wear resistance.

Available in different diameters to suit the geometry and thickness of your workpiece.

Brass with various copper-to-zinc ratios to optimize cutting speed.

Offered in various sizes, including 3.5Kg, 5Kg, 8Kg, and 16Kg, to meet different project needs.

Applications:

EDM wires achieve high precision in manufacturing and prototyping across industries such as aerospace, automotive, medical devices, and electronics.

Ideal for cutting complex shapes and fine details in metal workpieces.

Used in the production of high-precision molds and dies.

Suitable for creating detailed prototypes and parts.

Versatile for custom machining of unique and intricate components.

Utilized in industrial and production settings for creating detailed components and tooling.

Industries:

Aerospace

Automotive

Manufacturing

Electronics

Medical Devices

Specifications:

Tensile Strength: Various grades are available based on application requirements.

Fracture Resistance: Designed to handle high mechanical stress.

Conductivity: High conductivity with options for specific project needs.

Vaporization Temperature: Materials with high vaporization points to ensure reliability.

Hardness: Available in hard, semi-hard, and soft variations.

Wire Diameter: Multiple diameters to suit different workpiece sizes.

Brass Composition: Different copper-to-zinc ratios for optimized cutting performance.

Spool Sizes: Options of 3.5Kg, 5Kg, 8Kg, and 16Kg for flexibility in usage.

Enquire Form

Need Help?

+971 4 289 6166

Plain Brass

EDM wire is a critical component in the Electrical Discharge Machining (EDM) process, which is used for the precision cutting of complex shapes in conductive materials. This wire acts as the electrode through which electrical discharges or sparks are generated to erode material from the workpiece.

Product Features:

Available in various strengths to handle different stress levels during the EDM process. Higher tensile strength options are available for demanding applications.

Engineered for durability, ensuring the wire can withstand mechanical stresses without breaking.

High electrical conductivity, with brass wires being a popular choice for superior performance.

Made from materials with high vaporization temperatures to prevent premature breaking under extreme heat.

Hardness: Hard Brass Wires- For applications requiring high wear resistance, Semi-Hard Brass Wires- Balanced wear resistance and flexibility, Soft Brass Wires- Ideal where flexibility is more important than wear resistance.

Available in different diameters to suit the geometry and thickness of your workpiece.

Brass with various copper-to-zinc ratios to optimize cutting speed.

Offered in various sizes, including 3.5Kg, 5Kg, 8Kg, and 16Kg, to meet different project needs.

Applications:

EDM wires achieve high precision in manufacturing and prototyping across industries such as aerospace, automotive, medical devices, and electronics.

Ideal for cutting complex shapes and fine details in metal workpieces.

Used in the production of high-precision molds and dies.

Suitable for creating detailed prototypes and parts.

Versatile for custom machining of unique and intricate components.

Utilized in industrial and production settings for creating detailed components and tooling.

Industries:

Aerospace

Automotive

Manufacturing

Electronics

Medical Devices

Specifications:

Tensile Strength: Various grades are available based on application requirements.

Fracture Resistance: Designed to handle high mechanical stress.

Conductivity: High conductivity with options for specific project needs.

Vaporization Temperature: Materials with high vaporization points to ensure reliability.

Hardness: Available in hard, semi-hard, and soft variations.

Wire Diameter: Multiple diameters to suit different workpiece sizes.

Brass Composition: Different copper-to-zinc ratios for optimized cutting performance.

Spool Sizes: Options of 3.5Kg, 5Kg, 8Kg, and 16Kg for flexibility in usage.

Enquire Form