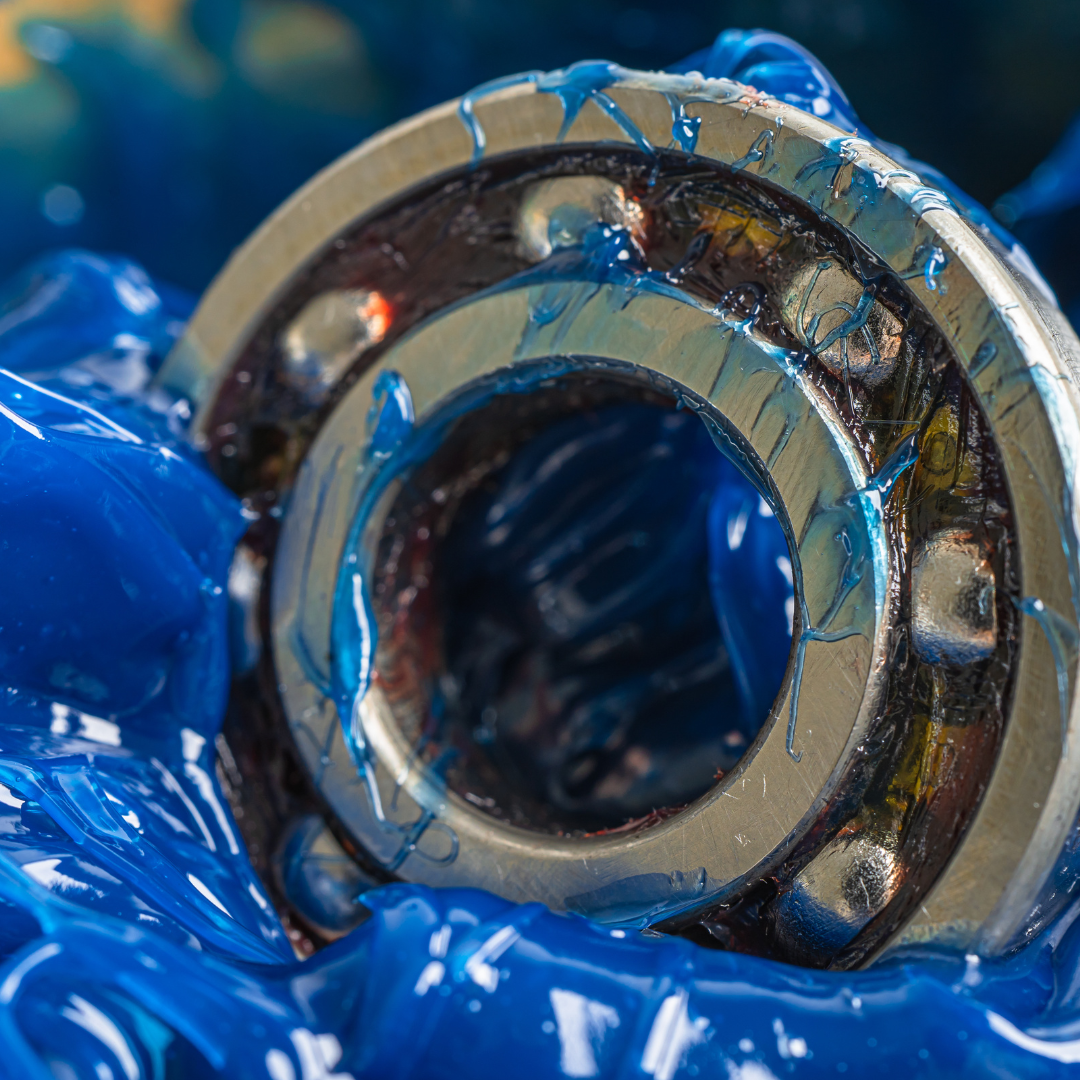

Lubricants Grease

Lubricant grease can lower friction, prevent wear, and perform various functions. Grease can be customized to suit specific requirements by utilizing different grades and types, guaranteeing top performance across a range of applications like automotive systems, industrial machinery, and manufacturing processes.

Product Features:

Decreases the amount of friction between contacting surfaces, reducing damage and deterioration.

Functions as an antioxidant, anti-wear, anti-foaming agent, emulsifier, and demulsifier.

Offered in diverse grades to meet varying needs and working environments.

Applications:

Lubricant grease is designed to facilitate the smooth functioning of machinery components in different industries, ensuring efficient operation and reducing downtime for various applications.

Lubricants also function as coolant agents in machines.

Guarantees that wheel bearings rotate smoothly and last a long time by offering constant lubrication.

Used on suspension parts, ball joints, and tie rod ends to stop damage and rust.

Essential for the lubrication of different types of bearings like ball, roller, and plain bearings to guarantee smooth and effective functioning.

Provides lubrication to winches, cranes, and other deck equipment in tough marine applications.

Lubricant greases are applied in turbines to guarantee dependable performance in high-temperature situations.

Industries:

Manufacturing

Machinery

Automotive Systems

Industrial Maintenance

Marine

Specifications:

Types of Grease:

Heavy-Duty Grease: Appropriate for high temperatures and heavy loads.

Red N Tacky Grease: Known for its ability to stick well and resist being washed away.

Marine Grease: Created to withstand water and protect against damage from saltwater corrosion.

Common Additives:

Anti-Wear Agents: Protect surfaces from abrasion and wear.

Antioxidants: Prevent degradation and extend lubricant life.

Anti-Foaming Agents: Ensure efficient operation by reducing foam.

Enquire Form

Need Help?

+971 4 289 6166

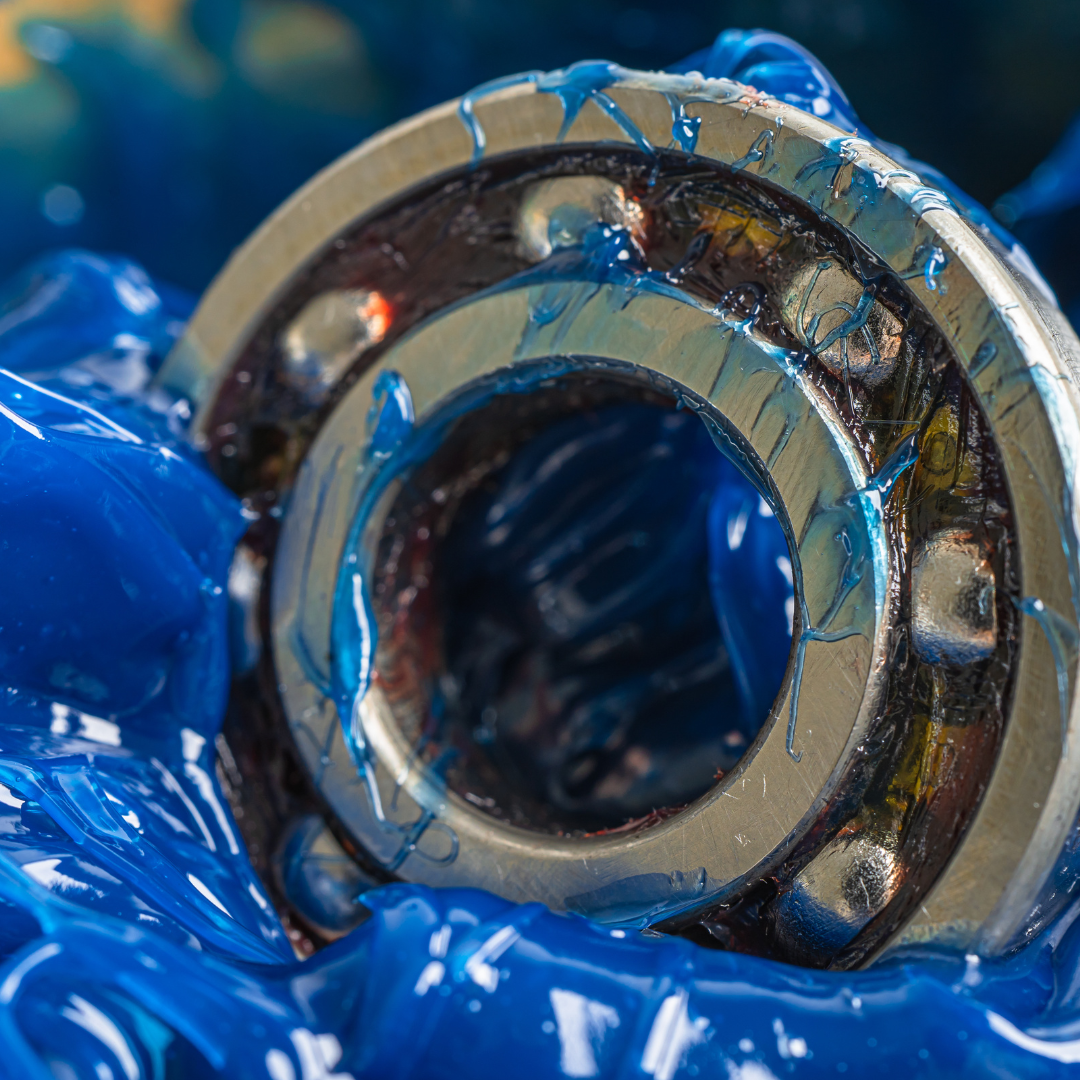

Lubricants Grease

Lubricant grease can lower friction, prevent wear, and perform various functions. Grease can be customized to suit specific requirements by utilizing different grades and types, guaranteeing top performance across a range of applications like automotive systems, industrial machinery, and manufacturing processes.

Product Features:

Decreases the amount of friction between contacting surfaces, reducing damage and deterioration.

Functions as an antioxidant, anti-wear, anti-foaming agent, emulsifier, and demulsifier.

Offered in diverse grades to meet varying needs and working environments.

Applications:

Lubricant grease is designed to facilitate the smooth functioning of machinery components in different industries, ensuring efficient operation and reducing downtime for various applications.

Lubricants also function as coolant agents in machines.

Guarantees that wheel bearings rotate smoothly and last a long time by offering constant lubrication.

Used on suspension parts, ball joints, and tie rod ends to stop damage and rust.

Essential for the lubrication of different types of bearings like ball, roller, and plain bearings to guarantee smooth and effective functioning.

Provides lubrication to winches, cranes, and other deck equipment in tough marine applications.

Lubricant greases are applied in turbines to guarantee dependable performance in high-temperature situations.

Industries:

Manufacturing

Machinery

Automotive Systems

Industrial Maintenance

Marine

Specifications:

Types of Grease:

Heavy-Duty Grease: Appropriate for high temperatures and heavy loads.

Red N Tacky Grease: Known for its ability to stick well and resist being washed away.

Marine Grease: Created to withstand water and protect against damage from saltwater corrosion.

Common Additives:

Anti-Wear Agents: Protect surfaces from abrasion and wear.

Antioxidants: Prevent degradation and extend lubricant life.

Anti-Foaming Agents: Ensure efficient operation by reducing foam.

Enquire Form