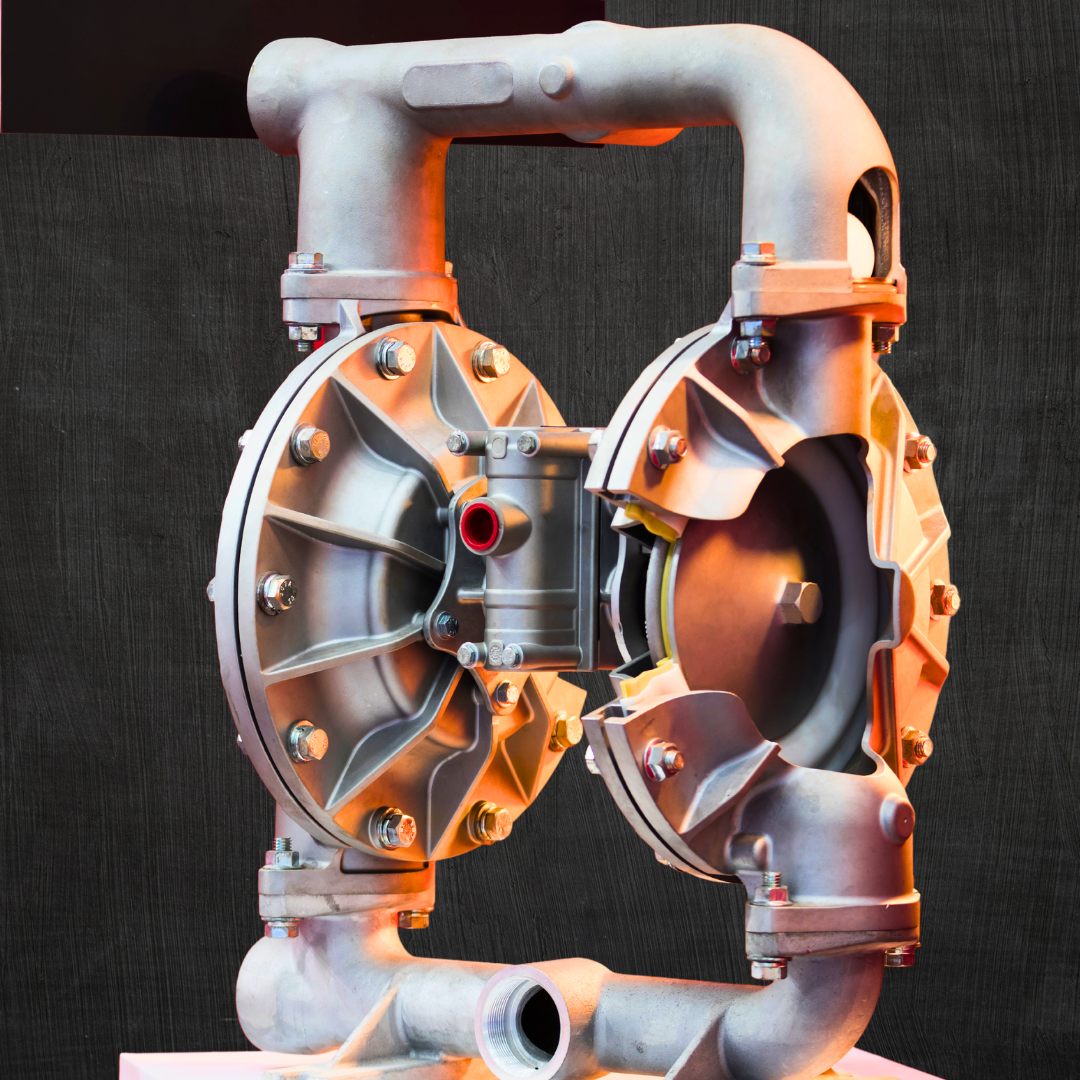

Diaphragm Pumps

Diaphragm pumps are adaptable and reliable fluid-handling devices used across various industries. They operate using a reciprocating diaphragm powered by air or electricity to move fluids. Known for their ability to handle a wide range of fluid types—from corrosive chemicals and abrasive slurries to delicate pharmaceuticals and food products—these pumps offer exceptional flexibility.

Product Features:

Versatile design with single or double diaphragms.

Available in various materials such as stainless steel, plastic, aluminum, and Teflon.

Operates via air or electric power, ensuring energy efficiency.

Capable of self-priming and handling fluids with varying viscosities.

Ability to run dry without damage, offering reliability and longevity.

Adjustable flow rates and pressures for precise application needs.

Easy to maintain with replaceable diaphragms and check valves.

Leak-free operation and explosion-proof models are available for hazardous environments.

Lightweight and portable models are available for ease of transport.

Applications:

Diaphragm pumps offer reliability and versatility, making them suitable for different applications and industries, ensuring efficient and safe fluid handling.

Ideal for handling corrosive and hazardous chemicals.

Effective in sludge and slurry transfer in treatment plants.

Used for pumping liquids, syrups, and semi-solids without contamination.

Ensures sanitary handling of sensitive fluids.

Suitable for transferring oils, fuels, and other petroleum products.

Robust models for handling abrasive and viscous mining slurries.

Used for transferring fertilizers, pesticides, and irrigation fluids.

Efficient in handling inks, dyes, and other printing fluids.

Industries:

Chemical Industry

Water and Wastewater Treatment

Food and Beverage

Pharmaceutical

Oil and Gas

Mining

Agriculture

Printing and Packaging

Specifications:

Flow Rate: Up to 300 gallons per minute (GPM), depending on the model.

Pressure: Capable of handling pressures up to 120 PSI.

Temperature Range: Operates in temperatures from -40°F to 350°F.

Viscosity Range: Suitable for fluids with viscosities up to 20,000 centipoise (cP).

Port Sizes: Available in port sizes from 1/4 inch to 4 inches.

Enquire Form

Need Help?

+971 4 289 6166

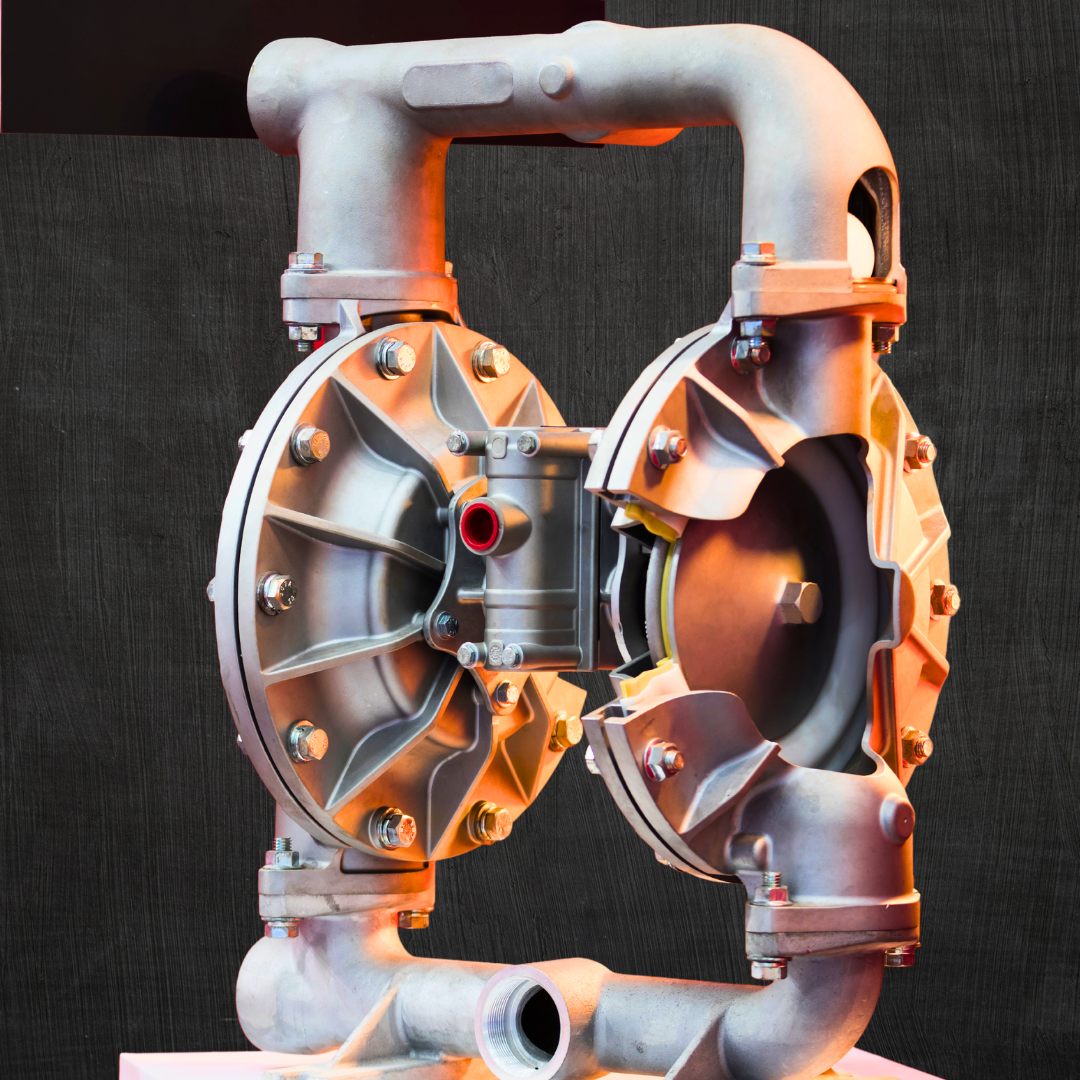

Diaphragm Pumps

Diaphragm pumps are adaptable and reliable fluid-handling devices used across various industries. They operate using a reciprocating diaphragm powered by air or electricity to move fluids. Known for their ability to handle a wide range of fluid types—from corrosive chemicals and abrasive slurries to delicate pharmaceuticals and food products—these pumps offer exceptional flexibility.

Product Features:

Versatile design with single or double diaphragms.

Available in various materials such as stainless steel, plastic, aluminum, and Teflon.

Operates via air or electric power, ensuring energy efficiency.

Capable of self-priming and handling fluids with varying viscosities.

Ability to run dry without damage, offering reliability and longevity.

Adjustable flow rates and pressures for precise application needs.

Easy to maintain with replaceable diaphragms and check valves.

Leak-free operation and explosion-proof models are available for hazardous environments.

Lightweight and portable models are available for ease of transport.

Applications:

Diaphragm pumps offer reliability and versatility, making them suitable for different applications and industries, ensuring efficient and safe fluid handling.

Ideal for handling corrosive and hazardous chemicals.

Effective in sludge and slurry transfer in treatment plants.

Used for pumping liquids, syrups, and semi-solids without contamination.

Ensures sanitary handling of sensitive fluids.

Suitable for transferring oils, fuels, and other petroleum products.

Robust models for handling abrasive and viscous mining slurries.

Used for transferring fertilizers, pesticides, and irrigation fluids.

Efficient in handling inks, dyes, and other printing fluids.

Industries:

Chemical Industry

Water and Wastewater Treatment

Food and Beverage

Pharmaceutical

Oil and Gas

Mining

Agriculture

Printing and Packaging

Specifications:

Flow Rate: Up to 300 gallons per minute (GPM), depending on the model.

Pressure: Capable of handling pressures up to 120 PSI.

Temperature Range: Operates in temperatures from -40°F to 350°F.

Viscosity Range: Suitable for fluids with viscosities up to 20,000 centipoise (cP).

Port Sizes: Available in port sizes from 1/4 inch to 4 inches.

Enquire Form