Cutting Oils

Cutting oil is a specialized lubricant and coolant used in metalworking processes to enhance tool performance and extend equipment life. It plays a crucial role in machining operations, including turning, milling, drilling, grinding, and threading, by reducing friction and heat generated during cutting.

Product Features:

Water-Miscible Coolants: Wide range of semi-synthetic and synthetic coolants and soluble oils designed to meet diverse lubrication needs. These coolants leverage advancements in unconventional emulsifying systems to cater to high-speed machining demands.

ULTRA – Grinding Fluids: Fully synthetic grinding fluids available in both transparent and colored options. These fluids have a regulated pH level to prevent the growth of bacteria, fungi, and yeast. The skin-friendly additives ensure safe handling.

ULTRA-COOL – Semi-Synthetic Coolants: Water-soluble semi-synthetic coolants with extended life forming transparent emulsions. They are EP (Extreme Pressure) capable, providing prolonged performance.

Environmentally Friendly Cutting Oils: Semi-synthetic, vegetable-oil-based, water-soluble metalworking fluids that are free from mineral oil.

Applications:

Cutting oil is crucial in various industries to ensure smooth operation, enhanced tool performance, and superior finish quality.

Used in lathes to cut or shape metal by removing material from the surface of a rotating workpiece.

Applied during the milling process to cool and lubricate the cutting tool and workpiece, improving the finish and extending tool life.

Essential for drilling operations to reduce friction, remove chips, and cool the drill bit, enhancing drilling efficiency and accuracy.

Applied during threading operations to lubricate and cool the threading tool, improving thread quality and reducing tool wear.

Essential for creating internal threads in a workpiece, cutting oil helps reduce friction and wear on the tap.

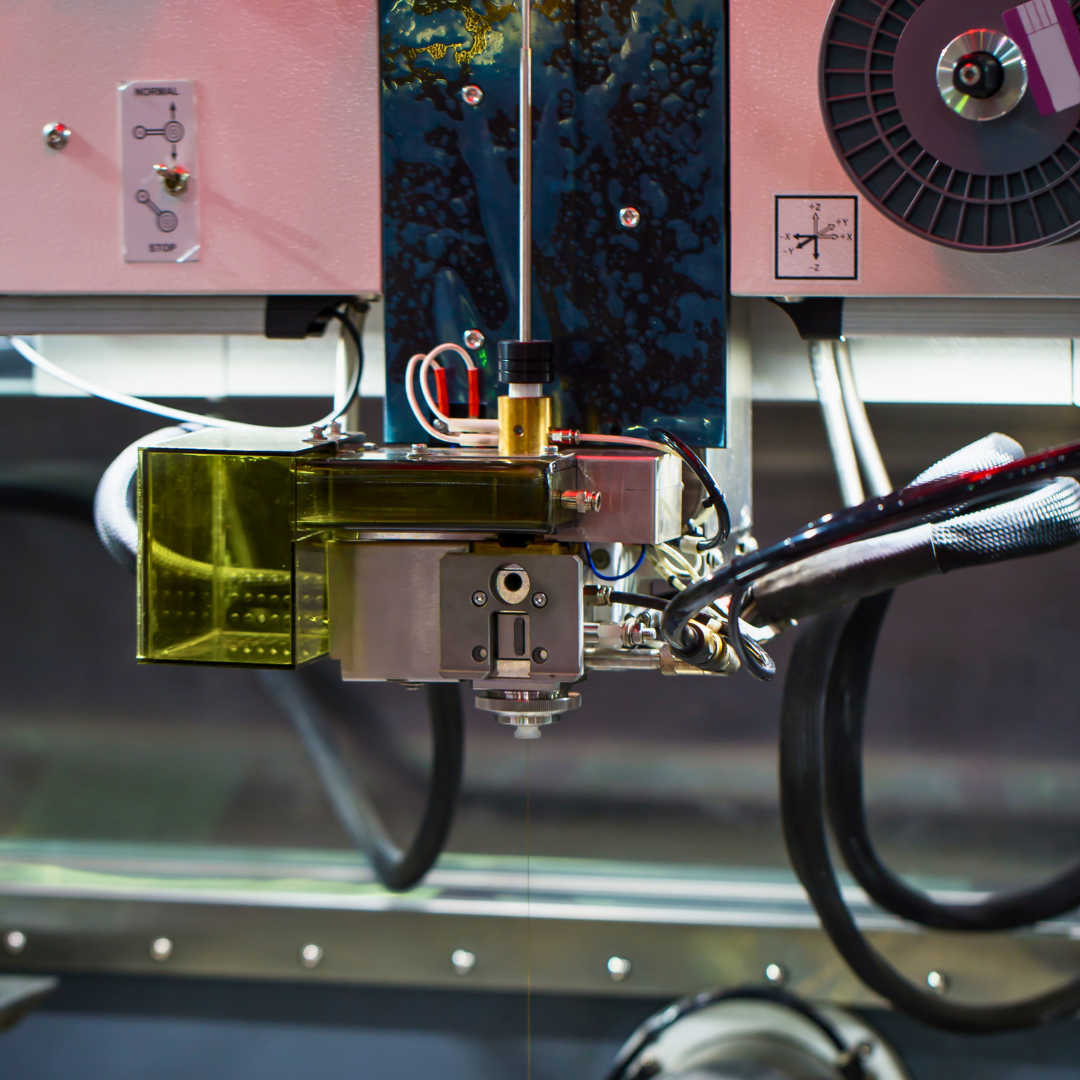

They are used in CNC machining to maintain optimal temperatures and reduce friction during automated cutting processes, enhancing precision and extending tool life.

Ideal for applications where environmental impact is a concern, providing effective lubrication and cooling without mineral oils.

Industries:

Drilling

Broaching

Milling

Threading

Specifications:

Water-Miscible Coolants: includes semi-synthetic and synthetic coolants and soluble oils designed for high-speed machining.

ULTRA – Grinding Fluids: Fully synthetic, available in transparent or colored variants, pH-regulated, skin-friendly.

ULTRA-COOL – Semi-Synthetic Coolants: Water-soluble, semi-synthetic with transparent emulsions, EP capable.

Environmentally Friendly Cutting Oils: Semi-synthetic, vegetable-oil-based, water-soluble, mineral oil-free.

Pack Sizes: Available in 20 & 205 liters.

Choosing the Right Cutting Oil:

Selection criteria include:

Machine type and operation speed

Desired lubrication and cooling performance

Environmental impact considerations

Cutting Fluid Categories:

Straight Oils: Non-emulsifiable, used undiluted, often with vegetable oils and esters.

Synthetic Fluids: Mineral oil and petroleum-free, made with alkaline organics and corrosion preventatives, best in diluted form.

Soluble Oils: Form emulsions with water, offering excellent lubrication and heat transfer.

Semi-Synthetic Fluids: Blend of soluble and synthetic fluids, balancing performance and cost.

Enquire Form

Need Help?

+971 4 289 6166

Cutting Oils

Cutting oil is a specialized lubricant and coolant used in metalworking processes to enhance tool performance and extend equipment life. It plays a crucial role in machining operations, including turning, milling, drilling, grinding, and threading, by reducing friction and heat generated during cutting.

Product Features:

Water-Miscible Coolants: Wide range of semi-synthetic and synthetic coolants and soluble oils designed to meet diverse lubrication needs. These coolants leverage advancements in unconventional emulsifying systems to cater to high-speed machining demands.

ULTRA – Grinding Fluids: Fully synthetic grinding fluids available in both transparent and colored options. These fluids have a regulated pH level to prevent the growth of bacteria, fungi, and yeast. The skin-friendly additives ensure safe handling.

ULTRA-COOL – Semi-Synthetic Coolants: Water-soluble semi-synthetic coolants with extended life forming transparent emulsions. They are EP (Extreme Pressure) capable, providing prolonged performance.

Environmentally Friendly Cutting Oils: Semi-synthetic, vegetable-oil-based, water-soluble metalworking fluids that are free from mineral oil.

Applications:

Cutting oil is crucial in various industries to ensure smooth operation, enhanced tool performance, and superior finish quality.

Used in lathes to cut or shape metal by removing material from the surface of a rotating workpiece.

Applied during the milling process to cool and lubricate the cutting tool and workpiece, improving the finish and extending tool life.

Essential for drilling operations to reduce friction, remove chips, and cool the drill bit, enhancing drilling efficiency and accuracy.

Applied during threading operations to lubricate and cool the threading tool, improving thread quality and reducing tool wear.

Essential for creating internal threads in a workpiece, cutting oil helps reduce friction and wear on the tap.

They are used in CNC machining to maintain optimal temperatures and reduce friction during automated cutting processes, enhancing precision and extending tool life.

Ideal for applications where environmental impact is a concern, providing effective lubrication and cooling without mineral oils.

Industries:

Drilling

Broaching

Milling

Threading

Specifications:

Water-Miscible Coolants: includes semi-synthetic and synthetic coolants and soluble oils designed for high-speed machining.

ULTRA – Grinding Fluids: Fully synthetic, available in transparent or colored variants, pH-regulated, skin-friendly.

ULTRA-COOL – Semi-Synthetic Coolants: Water-soluble, semi-synthetic with transparent emulsions, EP capable.

Environmentally Friendly Cutting Oils: Semi-synthetic, vegetable-oil-based, water-soluble, mineral oil-free.

Pack Sizes: Available in 20 & 205 liters.

Choosing the Right Cutting Oil:

Selection criteria include:

Machine type and operation speed

Desired lubrication and cooling performance

Environmental impact considerations

Cutting Fluid Categories:

Straight Oils: Non-emulsifiable, used undiluted, often with vegetable oils and esters.

Synthetic Fluids: Mineral oil and petroleum-free, made with alkaline organics and corrosion preventatives, best in diluted form.

Soluble Oils: Form emulsions with water, offering excellent lubrication and heat transfer.

Semi-Synthetic Fluids: Blend of soluble and synthetic fluids, balancing performance and cost.

Enquire Form