Horizontal Machining Centers: Your Guide to CNC Machines

Jul 30, 2024

When it comes to choosing the right horizontal machining center (HMC) for your business needs, there are several crucial factors to consider. The advantages of horizontal machining centers are undeniable, offering increased efficiency and precision in manufacturing processes.

To select the ideal HMC for your specific requirements, it's essential to evaluate key features and capabilities that align with your production goals. By investing in the right horizontal machining center, you can maximize efficiency, improve productivity, and achieve superior results in your manufacturing operations.

H & HUP Series

The heavy-cutting high-rigidity rectangular-guide horizontal processing center for H series is a machine tool structure that integrates international advanced design concepts, making it more suitable for heavy cutting of large parts. Known for its ultra-wide guide structure, the H series machining center boasts a wide processing range, catering to diverse machining needs.

On the other hand, the HUP series represents a high rigidity roller guide horizontal machining center with a modern design approach from an advanced international perspective. Featuring a T-type machine bed and hanging box layout, this series excels in delivering 3-axis high rigidity roller guide precision. The HUP series strikes the perfect balance between high precision and efficiency, making it ideal for a wide variety of rough and finish machining applications.

Key purpose and advantages of Horizontal Machining Centers

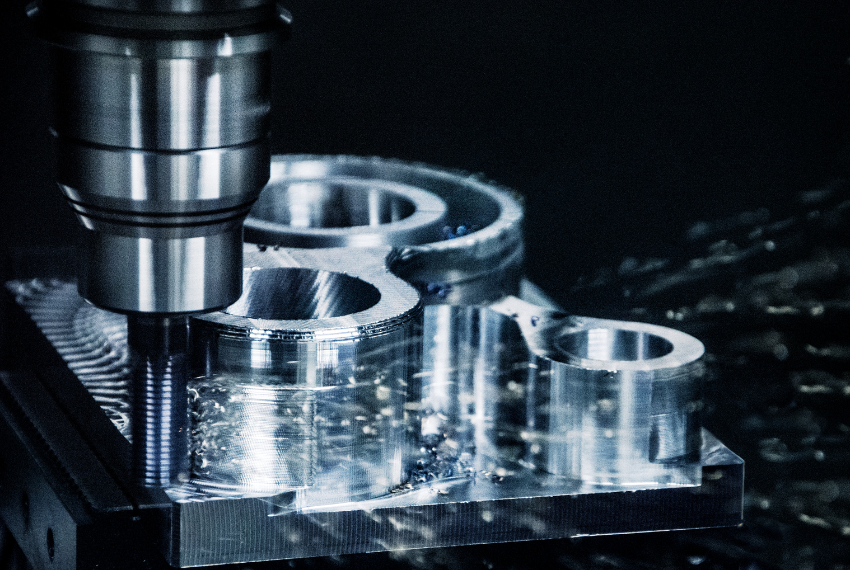

Horizontal machining centers (HMCs) are a type of machining tool used in manufacturing and metalworking industries. They are designed to perform various machining operations on workpieces positioned horizontally on the machine's table. The primary purpose of horizontal machining centers is to efficiently and precisely mill, drill, bore, tap, and perform other operations on metal or other materials.

Here are some key purposes and advantages of using horizontal machining centers:

Multi-Axis Machining: HMCs often feature multiple axes of motion, allowing for complex machining operations to be performed in a single setup. This capability enables the machining of intricate geometries and contours with high precision.

High Productivity: Horizontal machining centers typically have fast spindle speeds and rapid traverse rates, leading to increased productivity compared to traditional machining methods. They can efficiently remove material from workpieces, reducing cycle times and improving overall production throughput.

Versatility: HMCs can accommodate a wide range of workpiece sizes and shapes, making them versatile machines suitable for various applications across industries such as automotive, aerospace, medical, and mold making.

Reduced Setup Time: Horizontal machining centers often feature pallet changing systems that allow for quick changeovers between different jobs. This reduces downtime associated with setup and increases machine utilization.

Chip Evacuation: The horizontal orientation of the workpiece and the spindle in HMCs facilitates efficient chip evacuation. This helps maintain a clean work environment, prevents chip buildup, and enhances machining accuracy and tool life.

Heavy-Duty Cutting: HMCs are capable of performing heavy-duty machining operations on tough materials such as steel, titanium, and other alloys. Their robust construction and rigidity enable them to withstand high cutting forces without compromising accuracy.

Automation Integration: Horizontal machining centers can be easily integrated with automation systems such as robotic loaders and pallet changers, enabling unmanned operation for extended periods. This enhances productivity and reduces labor costs.

Overall, the purpose of horizontal machining centers is to provide manufacturers with a versatile and efficient solution for a wide range of machining tasks, ultimately improving productivity, precision, and cost-effectiveness in metalworking operations.

In the UAE and GCC region, Petrotek stands out as a leading supplier of HMCs, providing top-notch solutions for businesses looking to enhance their machining capabilities. By partnering with a reputable supplier like Petrotek, you can unlock new possibilities in manufacturing and take your operations to the next level.